Each day, we hear more and more about 3D printing and how it is being utilized in so many industries. The dental industry is no exception.

Chairside CAD/CAM milling systems have been on the market for over 30 years, but less than 20% of dentists have one. Will this also prove to be the case with 3D Printers in the dental office? Likely not, and here is why:

Broader array of clinical applications

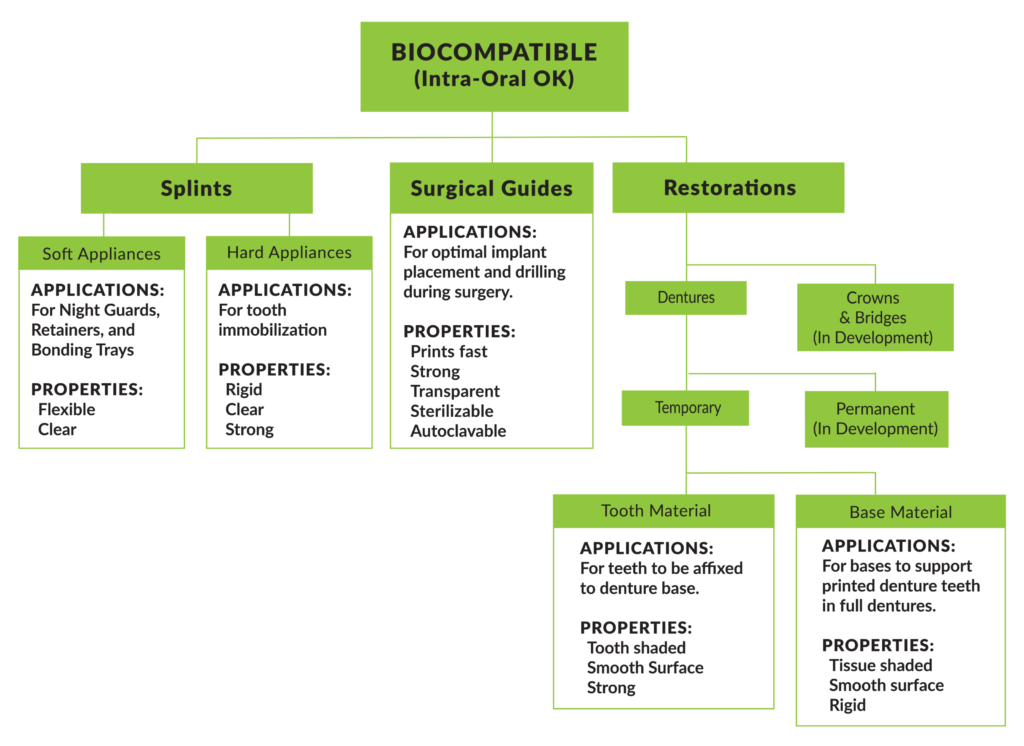

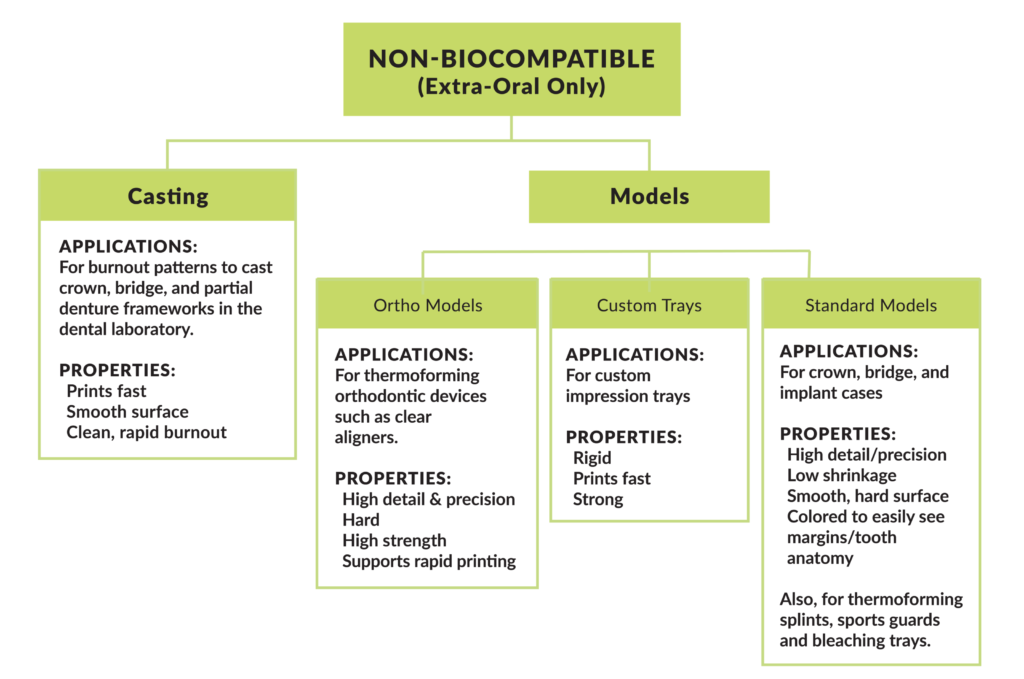

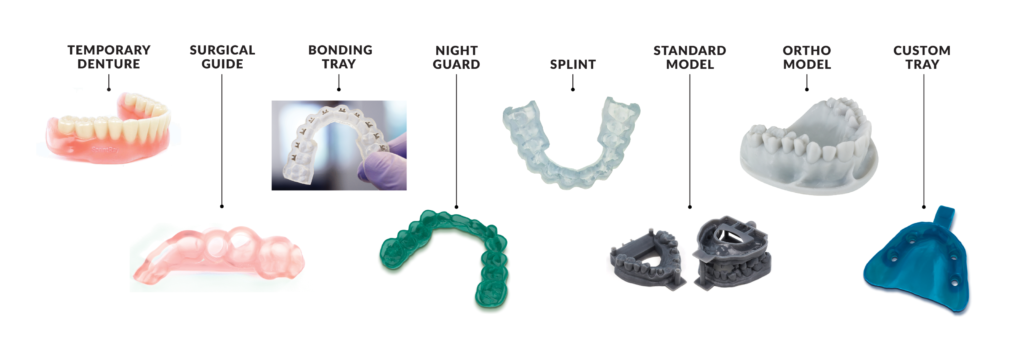

Consider all you can create in the office with today’s 3D printer technology and resin materials (see flowchart):

Highly Accurate Dental and Orthodontic Models

Implant Surgical Drill Guides

Bite Splints

Night Guards

Indirect Bonding Trays

Denture Try-in Bases and Temporary Dentures

Castable Crowns, Bridges and Partial Denture Frameworks

Custom Trays

Lower acquisition and ownership costs

Current 3D Printers designed for dental office applications run from $4,000 to $20,000+. Printing capacity, speed, and accuracy vary, so it is important to evaluate to determine the system that is right for your practice. When compared with the cost of chairside CAD/CAM Milling systems as high as $130,000-140,000, 3D Printing is proving to be a much more comfortable investment. It is important to note milling and 3D printing each serve different applications at this time. While this may change in the future, neither can fully replace the other.

A factor that is often inadequately evaluated is the cost of ownership. While some 3D printers may have very low acquisition prices, they may cost you more to operate over the course of the product’s life. For example, if the manufacturer requires you to purchase and use only their materials, you will likely pay more for those materials than if you use a system that is open to a variety of materials from several alternative sources. Also, some manufacturers require users to replace build trays more frequently than others. This can also drive cost of ownership way up. Don’t fall into the trap of thinking the system with the lowest acquisition cost is going to be the best value.

Other considerations

When evaluating 3D Printers, make sure the printer is compatible with and has available the types of resin materials you need for your intended applications (see flowchart). Support should also be carefully evaluated: Are loaner systems available? Are there any extra technical support or installation fees? Is technical support readily available should I need it? And don’t forget to consider warranty coverage… What is covered? What is the duration? Are extended warranty plans available?

What does the future of 3D printing in dentistry look like?

Very bright indeed… as mentioned earlier, 3D Printing does not replace chairside milling, or lab fabrication of permanent indirect restorations. However, materials and techniques are in various phases of development, testing, and regulatory review that may enable 3D Printing of not only temporary but also permanent crowns, bridges, inlays, onlays, and dentures. While it may take months to years for these materials to come on the market and build a reliable track record of performance, they promise to make 3D Printing one of the most potent tools in a dentist’s arsenal for treating his or her patients.

Category: Technology

Back to Articles